The manufacturing finishing industry describes a wide range of industrial processes, including electroplating and PCB plating, that are applied to the surfaces of manufactured products in order to attain specific properties. Typical applications include circuit boards (where applied copper becomes part of the circuitry itself), aerospace components, automotive parts and general fixtures and fittings.

The need for untainted water

The industry relies heavily on treated and filtered water in order to meet stringent standards for chemical purity and operational safety. This is because most of the applications used will centre around specialist plating baths, where the manufactured component or finished parts will be dipped into a plating fluid, in order to create a coating such as copper or zinc onto the finished item. This coating may have functional or aesthetic properties and may often combine the two; such as providing a high-shine finish with an anti-corrosion property to maximise lifespan.

The water used in these treatments must be absolutely pure, as any particulate could interact negatively with the finishing bath chemical mixes and damage or spoil the finished component parts. For this reason, the water must absolutely not contain unwanted extras such as minerals or organics, which can react with chemical processes and compromise the integrity or appearance of the final finish.

How does the process receive pure water?

Different factories will use their own specific processes and have particular needs for filtration and treatment systems that will depend on factors such as the available water source and flow, any existing treatments, housing availability, degree of filtration and cleansing required, particle micron ratings, available budget, on-site technical expertise and automation technologies and so forth.

Fileder recommends the use of bag, depth or surface filtration, also carbon cartridges and reverse osmosis systems with de-ionising resin for the plating industry.

Depth cartridges

Plating baths will always filter the housed plating liquids with a bag, depth or surface cartridge to remove any particulate that enters the bath as exposure to air and the components occurs. For example, bags, depth or pleated cartridges will be used to remove particulate in a re-circulating loop, and for when the waste build-up in the tanks needs to be disposed of. In this instance, the depth cartridges will be used to capture copper, zinc and other plating materials for safe disposal or remuneration. Typically, where an economic solution is required, polypropylene bags or spun-bonded filter cartridges are considered along with polypropylene wound or cotton cartridges.

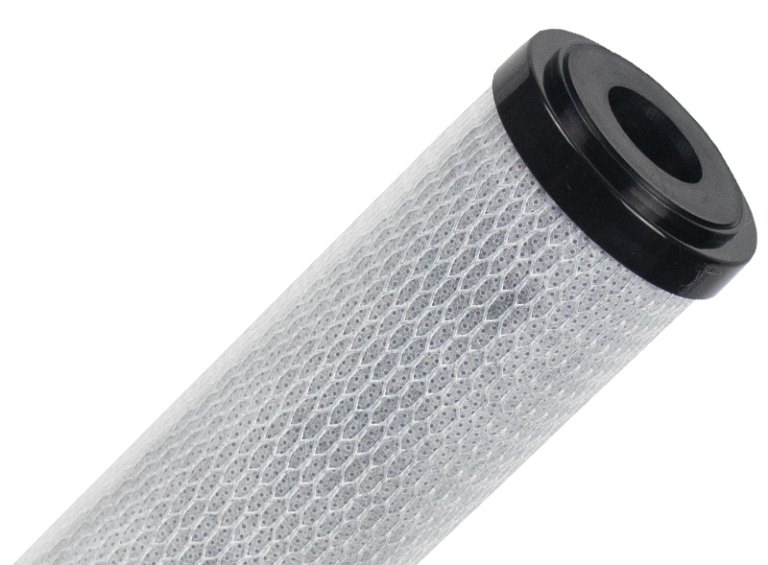

Carbon cartridges

Carbon cartridges may be used to remove the build-up of organics which are present in the plating bath liquid, to ensure that the unit for plating isn’t negatively affected by any surface pitting. Specific assessment and diagnosis of needs will be required as some of the plating industry’s multi-round housings tend to be larger in size than standard carbon cartridges, and SPECTRUM SFBC-EL cartridges are often preferred, thanks to their narrower diameter and high-purity carbon which doesn’t leach any sulphur into the plating bath, as well as retrofitting industry standard housings. The fixed gasket design also removes any risk of the gasket accidentally falling into the tank and contaminating the liquid.

Reverse osmosis and de-ionizing resin

All electroplating industries use pure water, and this can be made using reverse osmosis or de-ionising resin systems, according to the necessary volumes of water required. The pure water is needed for preparing, diluting and topping up of the plating fluids used, also for rinsing electroplated parts and for spot rinsing of extremely small parts and PCBs to ensure that no spots are present on the finished coating.

Fileder has been supporting manufacturing businesses with water filtration and treatment solutions for over thirty years and offers a broad range of technologies to suit varied needs, along with a highly responsive service mentality that keeps purchasing costs at a minimum whilst offering robust, quality products. Contact us to find out more.