Bag filtration uses a bag manufactured from filtering material. The bag sits inside the filter housing and as it fills up, the water passes through the tiny holes in the material and leaves behind unwanted particles. These systems are quick and easy to use, cost-effective and easy to maintain.

Bag filtration systems are an excellent option for water treatment scenarios where basic filtration and a high rate of water flow is needed. The technology is simple with the bag sitting in the opening of the filtration system using a sturdy ring. This can make bag filtration a good choice where the technology fits the user’s application needs and where the ease of installation is required. The main job of the bag filter happens at the point of water entry into the system and it acts to lessen the degree of sand, silt, dirt and other forms of sediment that are present in the water. Some models on the market come with particularly small micron ratings that can be used to filter out a certain amount of particulates, however, they will not remove bacteria or chemicals, such as chloramines. Additional water treatment systems are needed to remove both chemicals and unwanted bacteria.

Main applications

Bag filters are primarily used in industrial, agricultural and commercial settings and very rarely in homes. The benefit of bag filters for industries is that they can rapidly capture sediment whilst still allowing the flow of water to continue at speed. The water flow will not even be compromised if a larger single piece of sediment is captured in the bag, as the large surface area allows the water to simply flow around it. This is a key benefit over filters with naturally small openings, where trapped sediment can either stop or slow the water flow. Maintaining the flow of water is desirable for commercial applications, and it is possible to remove the bag filter easily and to take out the trapped material. Another key benefit of bag filters is that some types can be reused, making them a more environmentally friendly choice and supporting waste minimization.

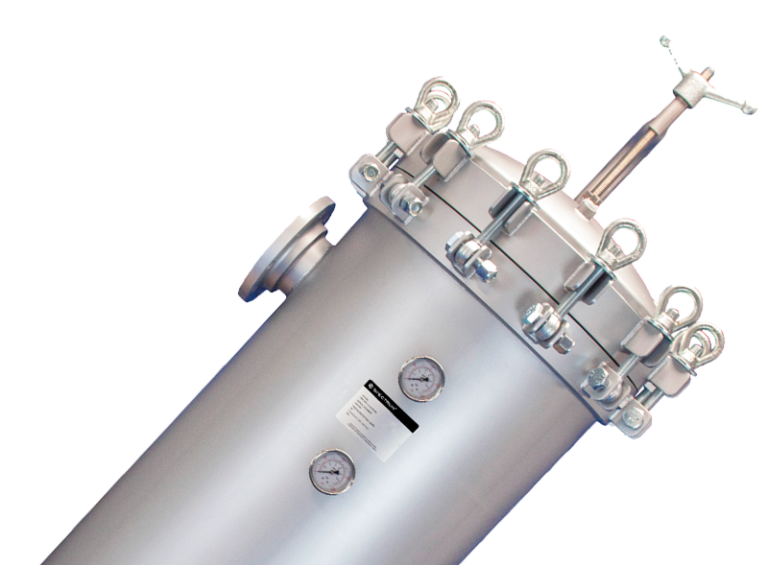

Choosing the right bag filtration system

Where the priority for water filtration is to remove sediment in a commercial, agricultural or industrial setting, a bag filter system may well be an excellent choice for your needs and there is a large variety on the market. The choice you will make will depend on factors such as the type and size of sediment that you will be filtering from the liquid. This will help you to choose the right micron rating, which defines the size of the filter holes in the bag, and also its material, which can include nylon, polypropylene or polyester. The type of sediment is another factor. For example, a filter housing made from polypropylene is preferred for applications where electroplating chemicals are present.

Another key consideration is the water temperature, as this will affect water performance, the water flow rate as this will affect the necessary micron rating that you need and the pH level of the filtered water, as this can impact the housing material. Fileder can help you to pick the perfect product for your need and budget and will carry out a detailed on-site assessment to fully understand the parameters of your operation and desired water quality.