Treating water prior to industrial boiler feed can save both time and money within the process. Reducing particulate and removing scale reduces the need for costly blowdowns and keeps systems online for longer, saving valuable energy and water.

Chemical

Treating water prior to industrial boiler feed can save both time and money within the process. Reducing particulate and removing scale reduces the need for costly blowdowns and keeps systems online for longer, saving valuable energy and water.

Reducing hardness that can reduce membrane efficiency, softening the water prior to treatment removes harmful calcium and replces it with easy to remove sodium. Employing a duplex system means water is available at any time and demands for water are met.

Mains water is often treated with chlorine to control microbiological growth. Removing this prior to reverse osmosis is imperative to preserve membrane life and retain optimum membrane performance. Carbon treatment also reduces organics and other chemicals that could impede membrane life.

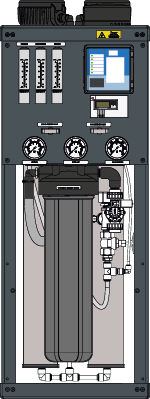

Reverse Osmosis removes unwanted TDS and reduces the need for "blow downs" in boiler systems. Purified water ensures high efficiency within the boiler system and reduces energy costs that can be associated with poor water quality,

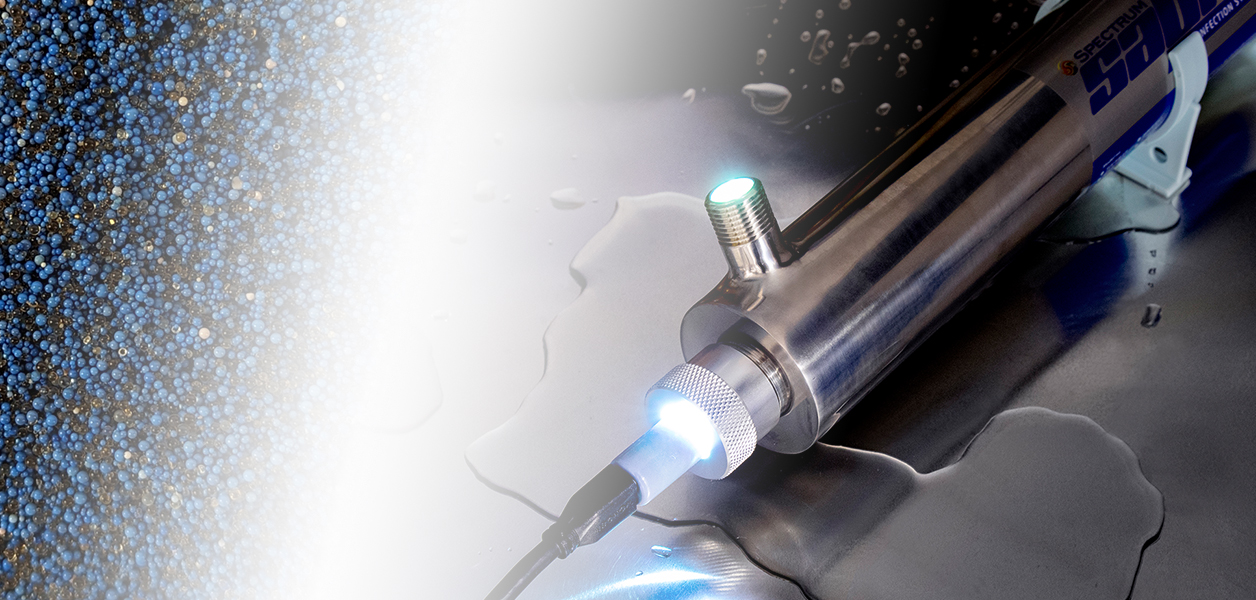

To protect stored water from microbiological intrusion, ultra-violet treatment sterilises the water prior to storage tanks. High powered UV disassociates the DNA within any potential bacteria, destroying it and preventing growth.

Sometimes added as a safeguard post storage, 0.2um absolute rated filtration can be added post tank to deliver sterile water prior to usage.

To protect water during the fill and empty process, vent filtration filters transferred air to microbiological levels utilising hydrophobic, PTFE absolute media.

Fourpure – Brewery

Redhill Farm Estate Vineyard – Winery

Britvic – Pure Water Production

RMC – Power Production

Koi Water Barn – Fresh Water Fish

Cirencester Hospital – Medical Device

Sorry, no form available.

Sorry, no resource PDF form available.