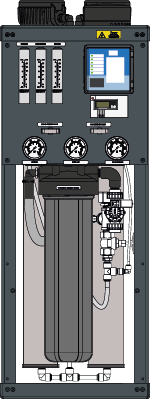

Incoming water is softened to prevent hardness commonly associated with membrane scaling, RO quality water is then produced at this stage and for further purification, DI resin is used to polish the remaining salts and ions.

Cosmetics & Toiletries

Incoming water is softened to prevent hardness commonly associated with membrane scaling, RO quality water is then produced at this stage and for further purification, DI resin is used to polish the remaining salts and ions.

Softening water prior to RO removes hardness commonly associated with membrane scaling. This enables RO systems to function more efficiently.

Purified water is produced using reverse osmosis membranes to separate the majority of salts and ions from the feed water and sending the salts and ions to waste or re-circulation.

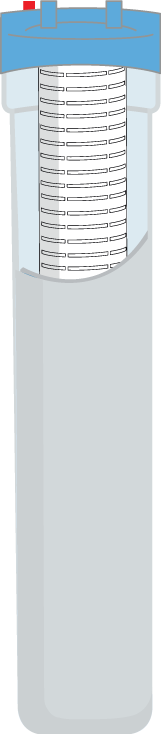

Utilising DI resin produces deionised water to 0.1us/cm conducting

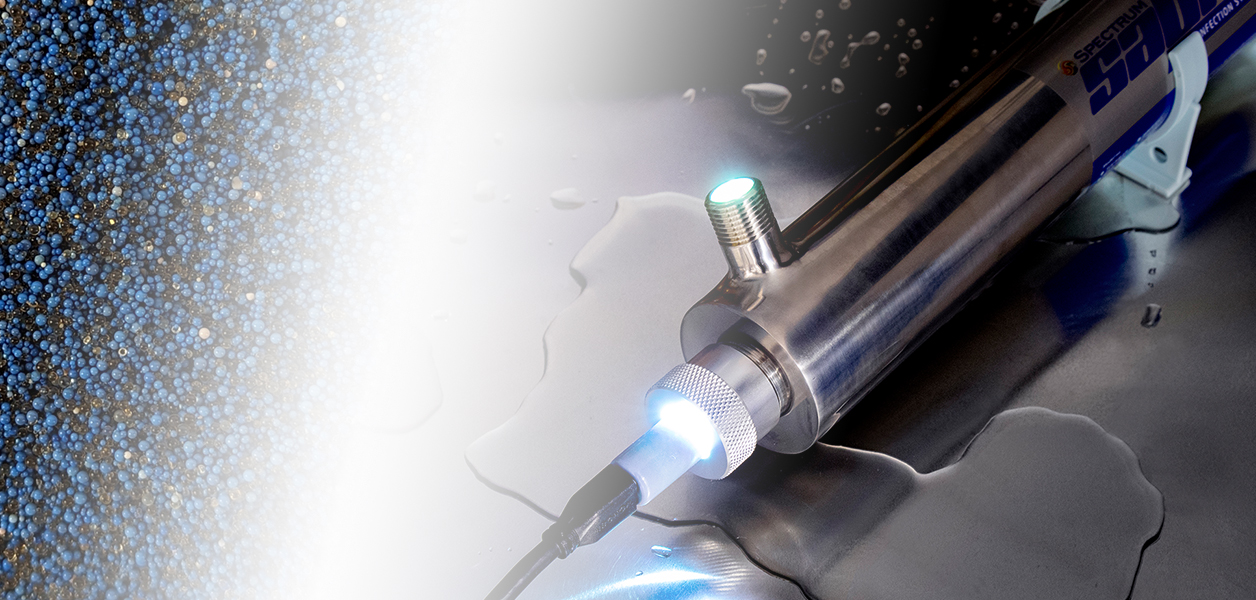

Prior to storage, UV light impedes bacterial growth by sterilising the DNA of microorganisms, suppressing bio-film and bacteria colony growth.

Final filtration to bacterial levels at 0.2 absolute safeguard, water prior to dispensing.

Fourpure – Brewery

Redhill Farm Estate Vineyard – Winery

Britvic – Pure Water Production

RMC – Power Production

Koi Water Barn – Fresh Water Fish

Cirencester Hospital – Medical Device

Sorry, no form available.

Sorry, no resource PDF form available.