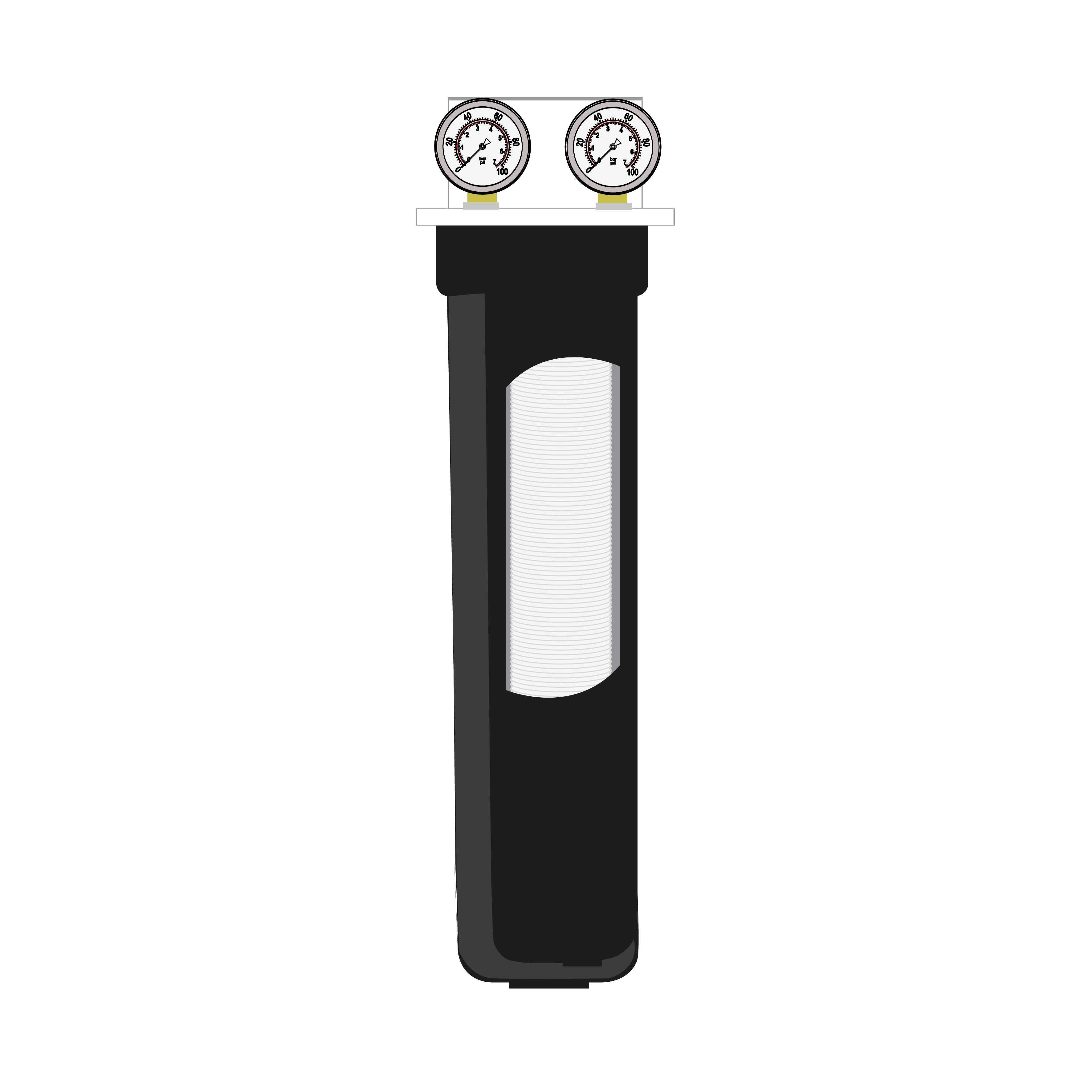

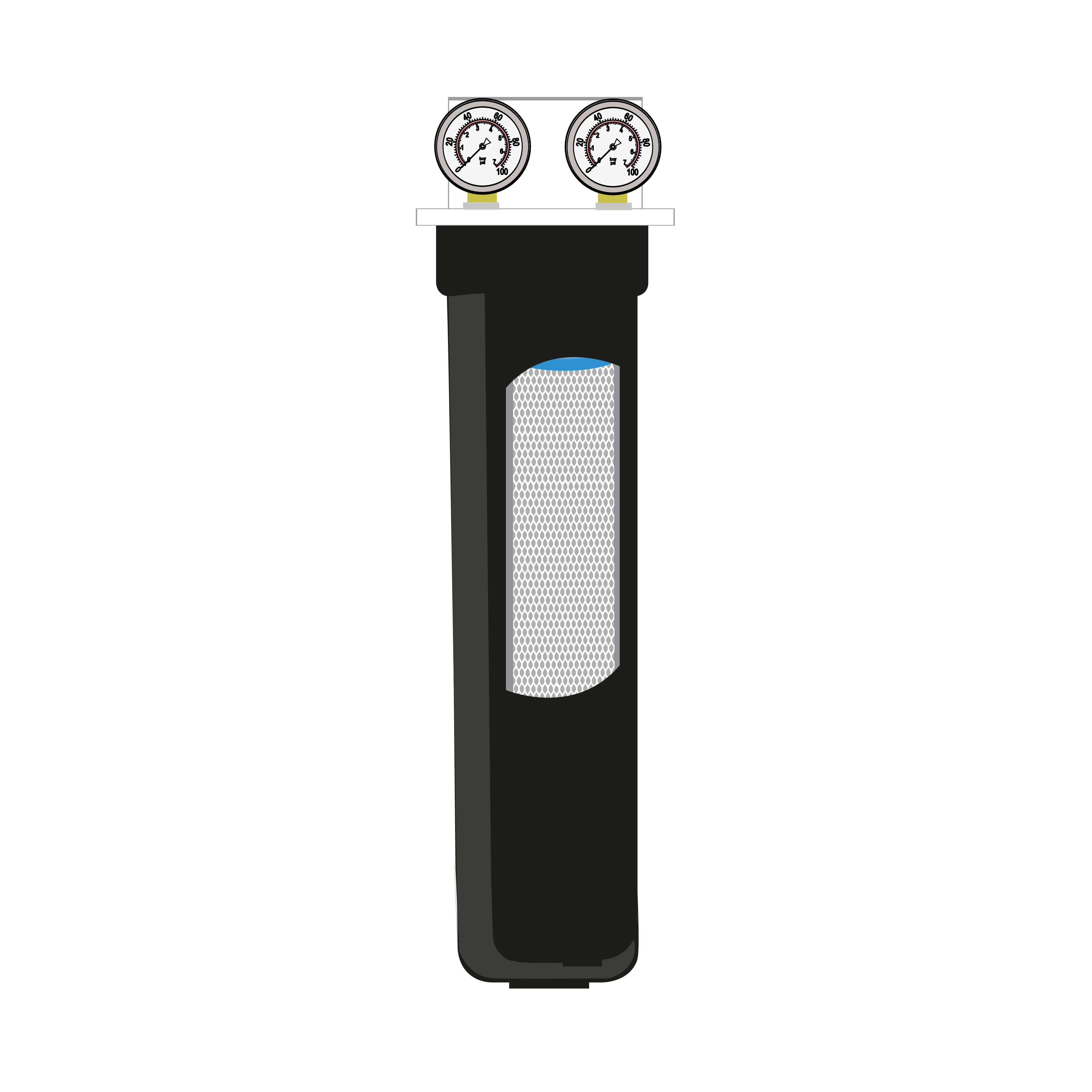

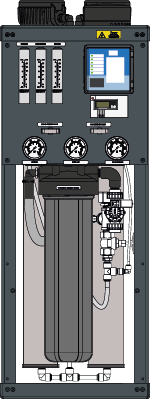

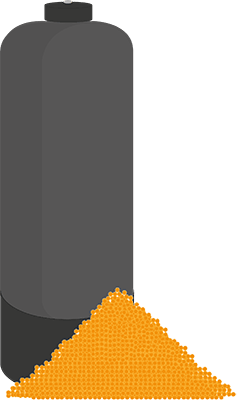

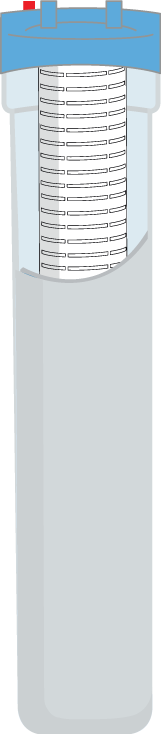

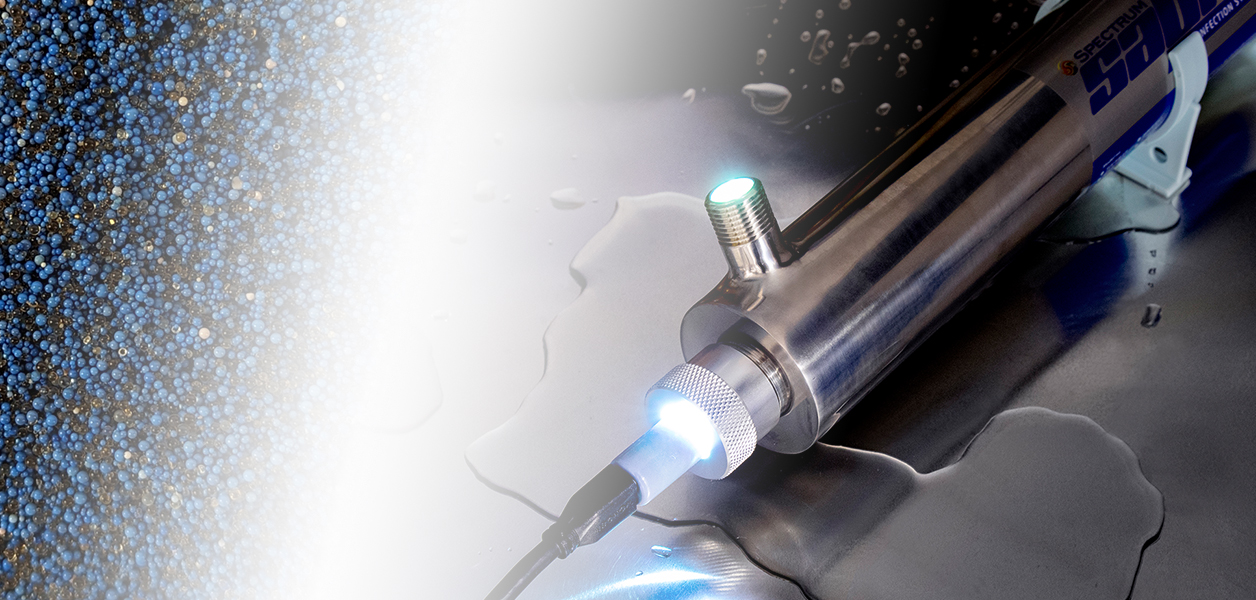

Incoming water is pre-filtered with sediment cartridges initially, this prevents further stages such as the carbon stage from premature blocking. Chemicals such as chlorine, chloramines, herbicides and organics are treated with carbon to protect the RO membranes from chemical attack. RO quality water is produced at this stage. For further purification, DI resin is used to polish the remaining salts and ions.